In our consultations with landscape architects, structural engineers, planners, and civil engineers, we often talk about projects that are designed in sensitive natural environments, such as mangroves or wetland areas. With these projects, there is always concern about protecting the area by considering materials, design, and method of construction.

Meandering boardwalk designs through wetlands or sensitive preserve areas can allow an architect or engineer to provide pedestrians with an up close and personal connection to an area left in its natural state, but it’s important to be careful not to disturb these delicate ecosystems.

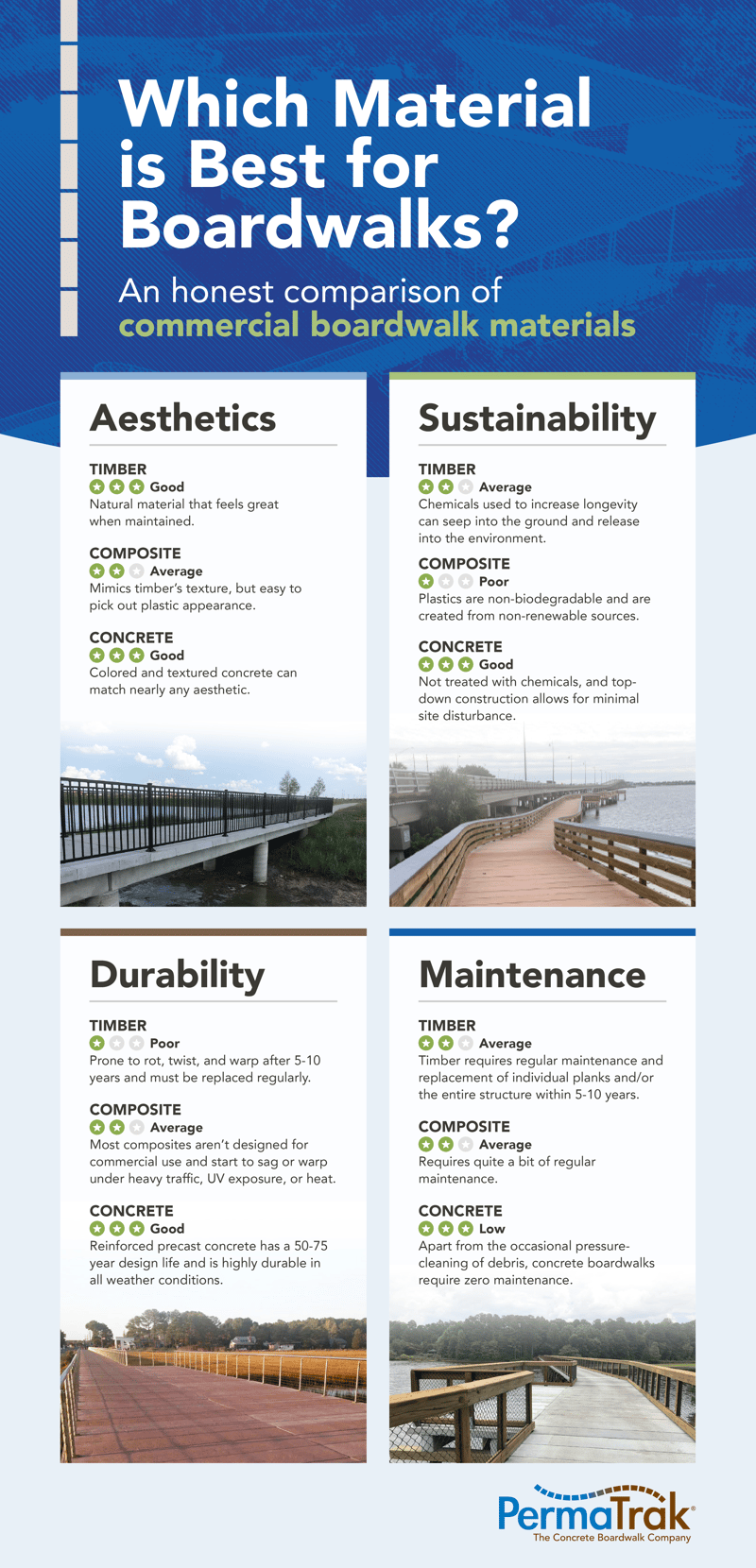

Whether the project includes boardwalks through a wetland, marsh or mangrove area, a concrete boardwalk will provide an ecologically-friendly solution. There are several advantages a concrete boardwalk can offer over conventional construction.

1. Precast concrete doesn’t use harmful chemicals

One of the notable benefits of precast concrete is that concrete does not require the use of harmful chemicals such as stains or sealants during installation. In contrast, these chemicals are often applied to other materials in an attempt to extend the boardwalk's lifespan, but they pose potential hazards to the delicate wetland ecosystem.

By opting for a concrete boardwalk, such as PermaTrak's system, the need for external chemical treatments is eliminated. The integrally colored precast concrete components used in PermaTrak's system* are designed to withstand the test of time without leaching any harmful substances into the surrounding wetlands, marshes, or mangrove areas.

*Colors include Adelaide Gray, Melbourne Tan, Natural Concrete, Daintree Green, and Savannah Brown.

This absence of harmful chemicals provides significant environmental benefits. Stains and sealants used in conventional materials can seep into the ground or be carried by rainwater, potentially contaminating the water sources within the wetland ecosystem. These chemicals may have adverse effects on the flora, fauna, and overall ecological balance, posing a threat to the sustainability of the wetland environment.

2. Precast concrete can be constructed using the top-down method

Top-down construction refers to the ability to install boardwalk treads and beams incrementally from equipment driven on previously installed treads and beams. With concrete, this can be accomplished under the right circumstances*, because the material can easily hold the weight of installation equipment.

A timber or composite wood boardwalk can be designed to support heavier equipment for top-down construction, but not without bigger and bulkier load bearing components (beams, headers, stringers, etc.). These extra steps typically result in a higher cost to the owner overall. Precast concrete's inherent strength and durability make it a naturally suitable material for top-down construction.

*Note: Top-down construction is often not the most cost-effective approach, especially when it's not required. Be sure to explore all of your options before deciding to move forward. If you would like to discuss the best installation method for your project, contact us here.

Animation showing top-down construction using the "Helical Piers from Boardwalk" method.

3. Precast concrete is manufactured before installation, eliminating field cutting

Precast concrete offers a significant advantage in minimizing the installation impact of wetland boardwalks through the elimination of field cutting. Field cutting, commonly required in traditional construction methods involving timber or composite wood boardwalks, poses a potential threat to the sensitive wetland ecosystem. When lumber is cut on-site, it can release preservative chemicals and sawdust that may leach into the construction site and ultimately find their way into the wetlands, causing harm to the delicate balance of the environment.

However, with precast concrete, the need for field cutting is completely eliminated. The engineering and layout work is meticulously performed prior to installation, ensuring that all necessary cuts and shaping of the concrete components are completed off-site in a controlled environment. This eliminates the possibility of sawdust or harmful chemicals making their way into the wetlands during construction.

4. Precast concrete shortens the overall construction time

Another way precast concrete reduces the installation impact of wetland boardwalks is by significantly shortening the construction time. Precast concrete components are manufactured off-site under controlled conditions, allowing for parallel construction processes. This means that while the boardwalk foundation is being prepared on-site, the precast concrete components can be simultaneously manufactured off-site. Once the components are ready, they can be quickly transported and installed, reducing the time spent on-site and minimizing disruption to the wetland environment.

The shortened construction time also helps to mitigate potential environmental risks. Traditional construction methods that involve extensive on-site fabrication and cutting of materials can lead to prolonged exposure of construction workers to wetland areas, increasing the chances of accidental spills or damage to the ecosystem. By utilizing precast concrete, the installation process is streamlined, minimizing the duration of construction activities and reducing the overall environmental impact.

5. Precast concrete provides long-lasting durability

The long-lasting durability of precast concrete minimizes the need for extensive repair or replacement work, reducing the overall disruption to the wetland ecosystem. Additionally, the reduced maintenance requirements contribute to long-term cost savings and environmental sustainability, making precast concrete an excellent choice for wetland boardwalk installations.

Overall, precast concrete offers multiple advantages in reducing the installation impact of wetland boardwalks. Its environmentally-friendly characteristics, ease of construction, preservation of natural aesthetics, and long-lasting durability make it a suitable and sustainable material choice for sensitive natural environments.