After 25 years of work in manufacturing, design and marketing of precast products, I find myself as the National Sales Manager of PermaTrak. With PermaTrak I have an opportunity to provide technical marketing for a newly introduced precast concrete product, one that is well engineered and durable. This is not unlike many previous stages of the precast concrete industry as new products were introduced.

Precast Concrete Pipe

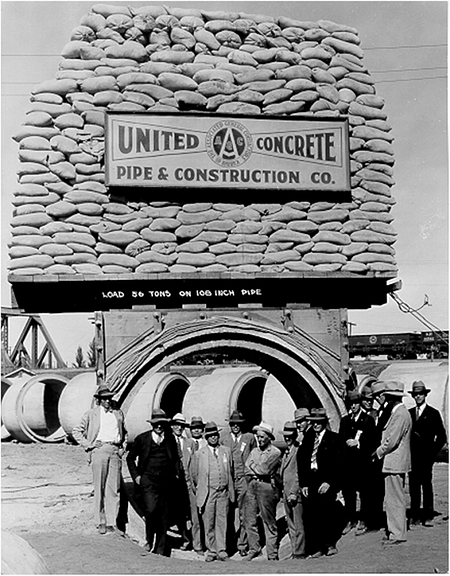

I started my career with New Orleans Cement Products, a precast concrete pipe company that was a local leader in developing alternative precast drainage structures. Thinking of my days at that plant helped me realize that since the introduction of precast concrete pipe in the 20’s and 30’s, precast concrete has improved, adapted and created new markets for designers and contractors. Specifications were enhanced, production efficiencies were made and many of those early concrete pipelines that were widely accepted are functioning well today. Concrete has been used for hundreds of years, and it has become the major material for construction worldwide. Post World War II, the use of precast concrete expanded as technology allowed for more acceptance of “prefabricated” materials. Precast plants were modernized and could produce a wide variety of pipe styles. These would meet or exceed specifications for large transportation projects and more custom site work. For more than half a century, most major drainage projects have included precast concrete pipe.

Booming Precast Concrete Product Manufacturing

During the 70’s and 80’s the pipe plants began producing and marketing additional precast utility products including larger diameter pipe. Those advancements were the result of a variety of improvements such as mix design technology, steel form efficiencies and supplemental concrete production accessories. Basic plant components like concrete batch plants were upgraded. These significant enhancements assured the plants maintained a high level of quality control. Soon contractors enjoyed the benefits of precast box culverts, utility vaults, manholes, catch basins, pavers and more. New production facilities were started to handle additional precast concrete production. Products included precast concrete bridges, precast pedestrian bridges, retaining wall systems and precast concrete panels. It was exciting to be a part of introducing new precast concrete products where only cast-in-place concrete had been considered previously. Those newer precast solutions are now a staple of any construction site. This shift in the construction industry was a terrific success and provided better alternatives through technology and innovation of precast concrete.

Precast Concrete Bridges

My technical marketing work with precast pipe and other products led me to a company that introduced a cost-effective, technically superior solution to cast-in-place box culverts. CON/SPAN Bridge Systems had the same features as previously designed precast concrete structures: thoroughly engineered, a durable long-term solution, simple to install and cost-effective compared to alternatives. CON/SPAN was used for transportation projects, drainage structures, pedestrian bridges, marine construction and environmentally sensitive sites. This product was an extremely successful innovation; thousands of these precast concrete bridges are installed and are still being designed as an industry standard.

More Innovative Precast Concrete Products

New precast concrete products are continually introduced as the pace of precast concrete innovation continues today. These products rely on innovations in engineering, new designs, improved production, quality control measures and technical marketing.

Those of us who enjoy the excitement of introducing new precast concrete products into the construction market always look for special products that arrive at just the right time. PermaTrak precast concrete boardwalk systems seem to be one of those products. Designers and their clients are encouraging physical activity through project design features such as bike trails, multi use paths and pedestrian friendly services. Recreational activities are being introduced in small communities and regional areas alike. Designers need cost-effective products to provide owners with accessible sites and reduced maintenance costs over time.

PermaTrak has only been introduced in the US for a few years. Designers continue to place an emphasis on products that will function well for the long-term. Today we find ourselves using precast concrete in project designs that include boardwalks, pedestrian bridges, trails, observation decks, marinas and greenways. I am excited to continue my personal career development with a new precast concrete product; one produced from a material with a 50-75 year design life that has been proven for hundreds of years.