When planning and designing golf cart bridges, architects and engineers have several variables to consider. Durability, cost, and safety – to name a few.

At PermaTrak, we specialize in precast concrete boardwalk systems specifically designed to meet your needs. Here are nine reasons to consider concrete boardwalk systems for golf cart bridge projects:

- Durability & Design List Costs

- Curved Alignments

- Bridge Clear Widths

- Beautiful Colors & Textures

- Simple Abutment Plan

- Ecological Benefits

- Safety & Slip-Resistance

- Professional Engineering Evaluation

- Engineering & Contractor Support

1. Durability & Design Life Costs

The durability of precast concrete is unparalleled, lasting upwards of 50-75 years per Army Corps of Engineers. Unlike wooden boardwalks which are prone to inevitable decay, rotting, and deterioration from the elements, concrete is able to withstand extremes from water to fire and everything in between.

Concrete is a great choice for crossings supporting golf cart traffic. Timber generally experiences excessive wear in the wheel path over time requiring unsightly repairs. Concrete tolerates this wheel traffic much better than timber, providing a smoother ride for the life of structure.

Its structural strength allows standard concrete beams (stringers) to span greater distances than wood, reducing foundation costs. The innate durability of concrete also directly translates to favorable lifetime maintenance costs.

A superior product, concrete requires only the occasional powerwashing, whereas wooden boardwalks often require expensive replacements of rotten/warped beams and full replacement in 10-15 years. While traditionally a bit more costly than timber at the onset (although the cost of lumber has increased dramatically in recent years), a lifetime cost analysis shows concrete as a preferable option.

Check out our article on Life Cycle Maintenance Costs to learn more about the cost of concrete vs. wood and composite materials.

2. Curved Alignments

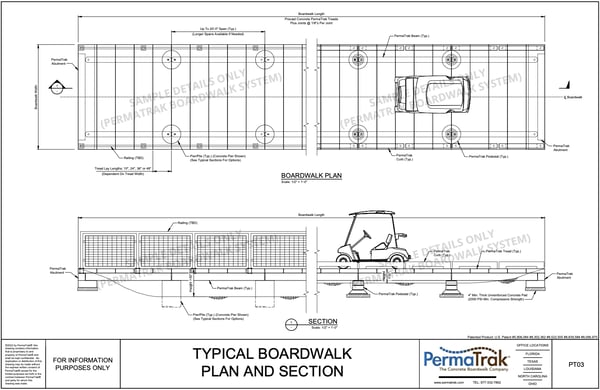

Plan, elevation, and cross sections for PermaTrak's concrete boardwalk system are nearly limitless, allowing architects and engineers to achieve their project visions.

Our product’s flexibility is intended to afford clients the ability to choose a design best suited for their unique project.

Curved alignments are accommodated by creating a series of wedge shaped treads, while horizontal alignments can be attained with a curvilinear or deflection angle approach.

3. Bridge Clear Widths

PermaTrak concrete bridges naturally lend themselves to creating up to 14 feet of clear width, easily accommodating two-way traffic for golf carts.

Other materials like prefabricated steel trusses and fiberglass systems are generally limited to projects with a more narrow clear width. Prefabricated solutions (steel or fiberglass) greater than 8’ will result in a permitted wide-load, leading to expensive, cost-prohibitive shipping. PermaTrak’s modular construction allows for wider systems to fit on non-permitted trucks.

While built in place timber can go wider than prefabricated steel or fiberglass, it does not provide the design life and no-maintenance advantages of concrete.

4. Beautiful Colors & Textures

A common concern when utilizing concrete in golf bridge projects is that it won’t fit into the design schematic and will appear gray, stark, and plain.

In reality, concrete boardwalk and bridge systems can be customized with a variety of colors and textures, allowing them to fit beautifully into endless designs.

PermaTrak offers a host of standard colors like Adelaide Gray and Melbourne Tan, as well as textures from BeachSand to BeachWood (see below), and can be customized upon request to allow clients to achieve their project’s high-quality look and feel.

| BeachSand |

BeachWood |

5. Simple Abutment Plan

When planning for the transition of a golf bridge at the beginning and end of the structure, it’s important to know the options associated with the bridge material you choose.

An appropriate abutment for your project will take into account geographical conditions, cost, safety, and ease of installation.

We are proud to share that single span abutments for PermaTrak bridges are ideally matched to all geographical conditions and can be installed in one day.

For more information on the five types of transitions we offer, click here.

6. Ecological Benefits

Unlike other materials like treated lumber and plastic-based composite systems, the production and installation of concrete boardwalks and bridges requires no heavy processing or toxic chemicals.

Made from sand, water, and coarse and fine stone, the PermaTrak system is a reinforced precast concrete product that does not release any gasses or toxic compounds into the environment. It is uniquely able to be installed in sensitive areas without physically disturbing the surrounding area, and can even contribute to your LEED or SITES credits. Read more about the eco benefits afforded by PermaTrak systems.

Precast concrete boardwalks can also be installed using top down construction where the boardwalk is installed from the top down, minimizing the impact on sensitive environments. Click here to learn more about top down construction.

7. Safety & Slip-Resistance

Golf bridge projects require an eye toward safety to mitigate the potential for slipping and tripping injuries and even lawsuits. Concrete boardwalk systems allow a project to attain a beautiful look as well as high levels of functionality and safety.

Timber planks can become dangerously slippery in wet and icy conditions. Boards can warp and twist, and screws can come loose as the wood expands and contracts.

Concrete planks, however, are not prone to warping. To increase slip resistance and traction, treads are precast with an integral textured surface, which significantly reduces risk without necessitating additional maintenance.

For more information about slip-resistance, check out our slip-resistance study comparing PermaTrak’s concrete boardwalk textures to composite timber, IPE wood, pressure treated timber, and rough cut timber.

8. Professional Engineer (PE) Evaluation

Our licensed engineers devote their time and expertise to ensuring the optimal design, construction, and operation of various projects. When working with PermaTrak, part of our process is to conduct a PE evaluation of the current state of your golf cart bridge. This allows us to assess whether a full or partial renovation is needed, scope of a project, timeframe, and materials necessary for achieving the project goals.

9. Engineering & Contractor Support

At PermaTrak, our team is hands-on throughout the entire project. We provide complimentary schematics and engineering drawings and work with you to decide on the best look and feel for your unique project. When the project moves to the construction phase, we provide on-site installation support for contractors.

Your Next Golf Bridge Project

There are countless considerations associated with golf bridge projects, and the materials you choose must allow you to meet your project’s needs.

Contact PermaTrak to discuss your unique vision and we can help you achieve your project goals.