Form Title

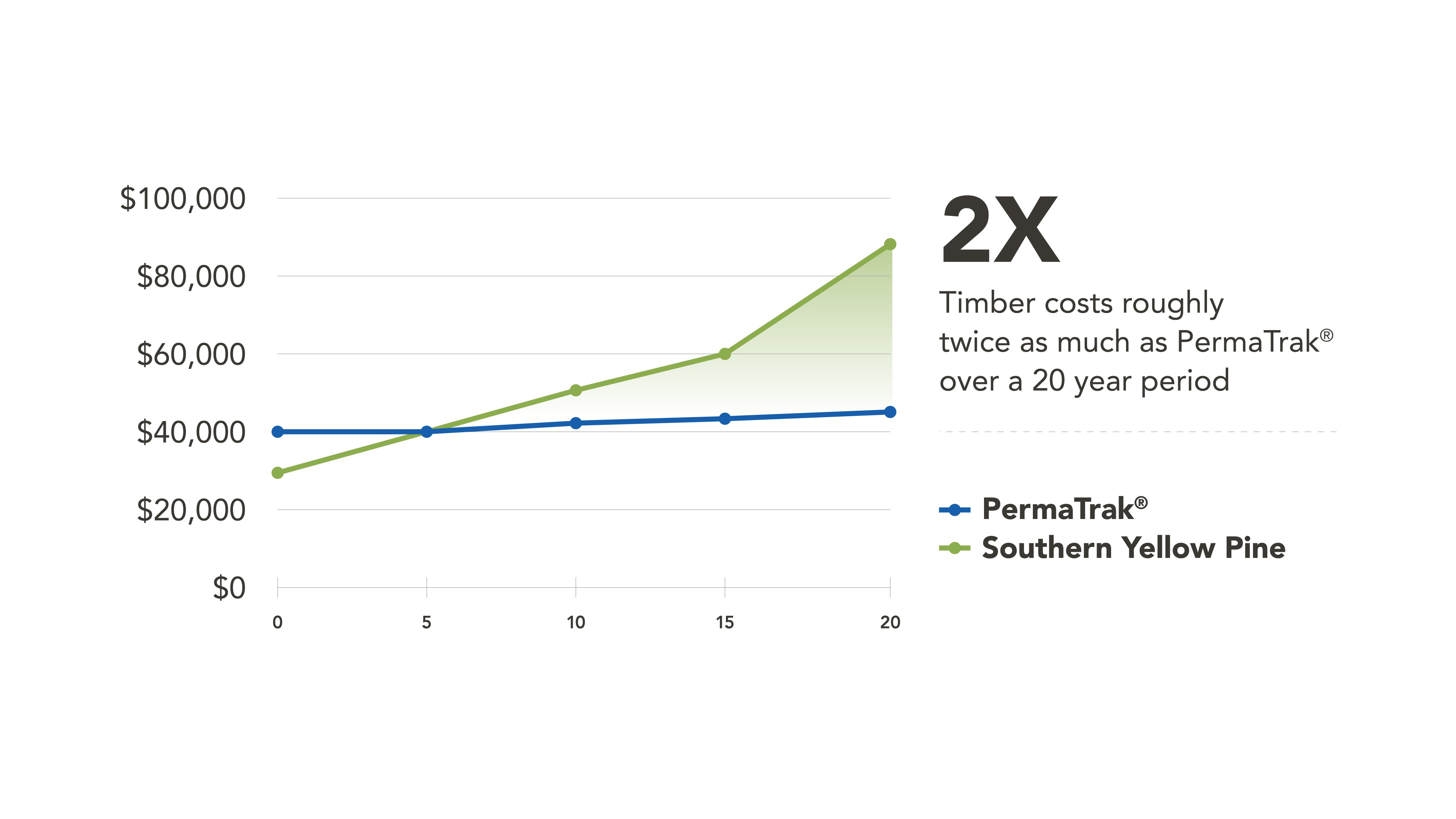

The following maintenance cost comparison was generated by Hamilton County Park District in Hamilton, OH. The application involved a narrow 160' wetland boardwalk leading to a 40' observation deck. The design live load requirement was pedestrian only.

A pressure treated timber boardwalk system was given a life expectancy of 16 years. After 16 years of use, the structure was to be demolished and replaced. You can see the hike in life cycle structure costs at year 16 on the graph below. The County accounted for a timber boardwalk powerwash and sealer application every 4 years, estimated at $1.50/SF. Lastly, maintenance funds were allocated new screws/tightening old screws, and replacing individual boards once they had deteriorated or warped too badly.

The County planned to powerwash the PermaTrak wetland boardwalk once every 4 years at a cost of $1/SF. This was the only maintenance item presented.

Conclusions:

- After 20 years, the cost of the timber structure was roughly 2x that of PermaTrak's wetland boardwalk.

- After 40 years, a timber structure would cost the County over 4x that of the PermaTrak structure.

The PermaTrak boardwalk system was originally invented in Australia in the mid-1990's.

Without any maintenance, the photos on this page show what the PermaTrak boardwalk photo looked like in 2009 and 2014, respectively.

Without any maintenance, the photos on this page show what the PermaTrak boardwalk photo looked like in 2009 and 2014, respectively.

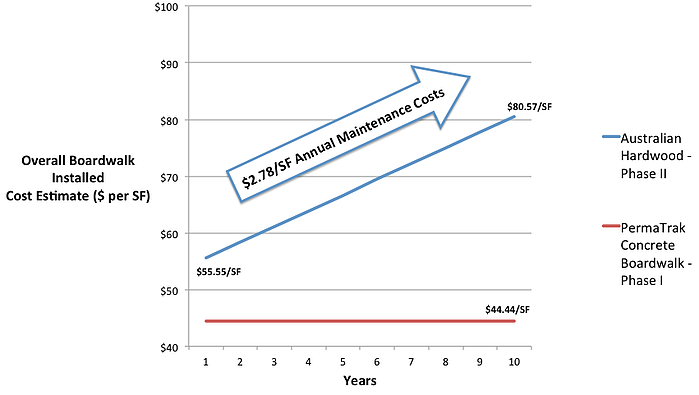

With two common boardwalk materials present on Granite Island in Adelaide, Australia, this project offers a good example of life cycle maintenance numbers. As a popular tourist destination in a coastal environment, both boardwalk materials are subject to harsh weathering conditions.

- PermaTrak was installed in 1996 during Phase I of this project, totaling an estimated 7200 SF.

- An Australian hardwood material was installed on an estimated 1350 SF in 1999 during Phase II.

Designers saw this hardwood material as more suitable for use as steps up the face of the island. Phase II of construction included a boardwalk, steps and a series of small viewing platforms.

Conclusions:

Over a period of 20 years, 1996-2016, no maintenance has been required for PermaTrak's concrete boardwalk. By comparison, the Australian hardwood material has required:

- Annual coating of Lanotec oil-based spray to minimize warping/splitting

- Annual maintenance program of re-tightening stainless steel screw connections

- An estimated $2.78/SF in annual maintenance costs ($3,753 annually)

| Maintenance Cost | Fire Resistance or Fire Rating | Twist / Warp | Splinters | Color Fade | Rot / Decay | |

|---|---|---|---|---|---|---|

| Southern Yellow Pine - Pressure Treated | $$$$ | Combustible Class C Resistance | High | Yes | Med | High |

| Composite Decking - Standard Plastics | $$$ | Combustible Class C Resistance | Med | No | Low | Low |

| Hardwoods - Ipe | $$ | Combustible Class A Resistance | Low | No | High (Stain / Sealer Rec) | Low |

| PermaTrak - Pre-Cast Concrete | $ | Noncombustible Hourly Fire Ratings | None | No | No | None |

Flexbox Module

Sub HeadlineHere is some copy

- Item 1

- Item 2

- Item 3

Safety Features

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Duis finibus sit amet purus et posuere. Aliquam tempus congue ante sed scelerisque. Nam erat mauri.