Foundations

Engineers and landscape architects have plenty of material options in designing a foundation system, including concrete, steel, timber, and composite.

Continue to read through the information below if you're looking to find the answers to any of the following questions:

- I have a boardwalk project through a wetland area; what are my foundation options?

- Which foundation types are most cost effective? Can I use timber piles with your PermaTrak system?

- If so, how do the piles connect?

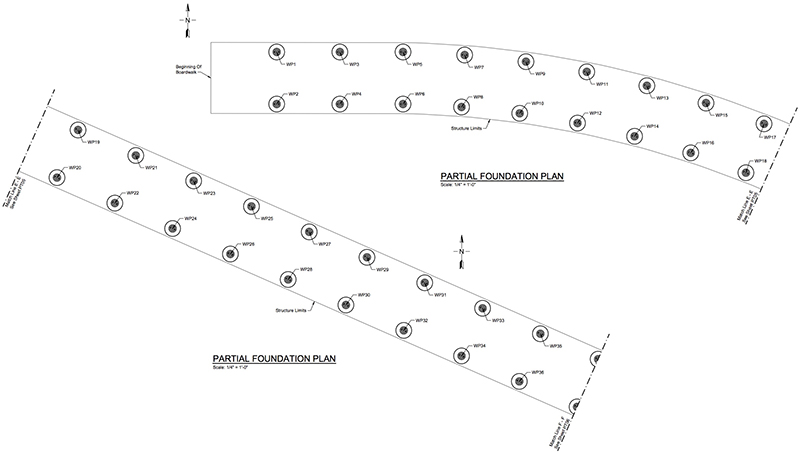

As always, our professional engineering team is available to discuss boardwalk design and engineering team is ready to assist landscape architects and engineers who are researching their boardwalk materials options. We offer engineering and CAD support details for PermaTrak projects that range in foundation type from precast pier to driven pile.

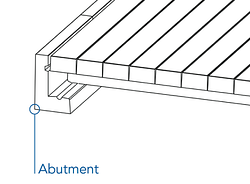

PermaTrak Abutment Component

- Shallow foundation component

- A PermaTrak standard component

- Typically used at the beginning or ending of the boardwalk run

The precast concrete abutment is an “L-shaped” shallow foundation component, much like a conventional bridge beam seat. It is typically used at the beginning or end of the boardwalk run. They are designed for lateral earth pressure against one side and for the load transferred from the beam and tread combination from the first span.

The precast concrete abutment is an “L-shaped” shallow foundation component, much like a conventional bridge beam seat. It is typically used at the beginning or end of the boardwalk run. They are designed for lateral earth pressure against one side and for the load transferred from the beam and tread combination from the first span.

This abutment component may rest on a bed of compacted stone or an unreinforced cast in place pad (aka "mud mat") so that load can be transferred uniformly to the in-situ soil. These abutments contain a horizontal reveal positioned to receive the first groove on the adjacent tread. The beam seat of the abutment has a semi-circle shaped valley for proper seating of the precast beams.

We also design for other types of trail transitions - check out our recent blog article for more information.

Precast Concrete Piers

Supplied by PermaTrak- Shallow footing option

- Most cost-effective

- Stackable components consisting of base, riser(s), and cap

- Can stack additional risers up to 3.5' in height above grade before additional bracing is required

Precast piers are advantageous to engineers and designers for many reasons. First, these relatively-light components are easily handled in the field by laborers or small lifting equipment such as a Bobcat®. Taller piers are achieved by adding risers to the precast pier. Typically 42'' is a maximum total height for a precast pier. Second, precast piers allow for fewer disturbances to the sub grade and surrounding areas than driving deep foundations. Read about projects (specifically Mellow Mushroom, Judaculla Rock, Robertson Park, Kaiki Trail) that have taken advantage of using this low-impact foundation system here.

If feasible, we recommend using this precast concrete pier system; it is the most cost-effective foundation option for a commercial boardwalk. See the step-by-step boardwalk construction process here.

Cast-in-Place Concrete

Shallow Footing Option- Typically more cost-effective than a deep foundation option

- Circular or square

Cast-in-place concrete shallow footings are typically circular or square, and commonly formed with a Sonotube form. The Sonotube (or equal product) acts as a stay-in-place form. The advantages associated with concrete piles (durability & longevity) are realized with this method. Shallow footings may be preferred over deep footing options since they require smaller equipment and are simpler to form and construct, resulting in lower costs. See the step-by-step installation process of a concrete boardwalk on CIP shallow footings here.

Timber Piles

- Deep foundation option

- Typically on the cheaper end of all deep foundation types

- 10" and 12'' diameter most common

- Typically 10' to 40' total pile length

- PermaTrak cap secured to top of pile transitions from foundation to PermaTrak system

Throughout the Gulf Coast region of Alabama, Mississippi and Louisiana, Pressure Treated timber piles (aka timber poles) are the most common deep foundation option for commercial boardwalks. 12’’ diameter piles are often specified.

Several variables will impact the price of timber pile installation: site access, diameter of pile required, required driven depth, geographic region, total number of piles, soil conditions, etc. The PermaTrak precast cap is then affixed to the top of the timber pile with a lag screw. See the step-by-step timber pile installation process here.

Composites - Fiberglass Piles

- Deep foundation option

- Durable

- Lightweight

- Shapes similar to conventional deep foundation options (circular)

- Cost ranges between timber piles and precast concrete driven piles

Drilled Shaft or Concrete Caisson

- Deep foundation option

- Sizes vary from 12" to 42" in diameter

This type of deep foundation is a reinforced, concrete member typically formed by advancing a temporary or permanent casing. Once a hole is cased, reinforcing is placed and concrete is poured inside. Sizes typically vary from 12’’ to 42’’ in diameter for PermaTrak boardwalk applications.

When designing a boardwalk on cast-in-place caissons, designers will consider site conditions, industry standard casing sizes, and finished boardwalk elevation (height above grade). All of these factors influence the structural engineer’s design for diameter and depth of the caissons. The photo above from a multi use path project shows a walking surface at roughly 5-6’ above grade.

Steel Piles

H-pile or Pipe- May not require dewatering for installation

- High pile capacities possible

- Circular or square

- Cannot be installed top-down

This type of foundation is a steel member. These durable piling systems may not require dewatering for installation, offering potential long-term cost savings for harsh environments such as floodplains or over bodies of water. Common shapes are H-piles and open pipe shapes.

Helical Piles

- Minimal disturbance

- Cost-effective deep foundation option

- Can be installed using smaller equipment

- Can be installed top-down

Steel piles may provide several distinct advantages over timber or concrete foundations for your project site. Helical “screw” piles may also provide a solid foundation option. Helical "screw" piles may provide a solid foundation option. These piles are typically advanced in sections, allowing for much lighter driving equipment to be used. For example, this type of foundation lends itself well to a wetland boardwalk application where top-down construction is required.

Micropiles

- Smaller than traditional pipe piles

- Can be installed in low overhead situations

- Good choice for areas sensitive to noise or vibration

Micropiles are smaller in diameter compared to other foundation options and can be installed with smaller drilling equipment. They are a cost-effective solution for low overhead conditions such as under existing bridges or overpasses, and offer minimal disturbance to tree roots.

Driven Precast Concrete Piles

- Deep foundation option

- Durability and longevity

- Higher cost than most foundation systems

Similar to steel piles, precast concrete piles are less commonly used for lightly loaded boardwalk applications. Typically manufactured in circular or square shapes, they provide a durable deep foundation option. The PermaTrak cap attaches similarly to other concrete options with a steel dowel and epoxy connection.