.png?width=600&height=336&name=Top-Down-Construction-Shot-Pouch-Greenway-Sumter-SC-permatrak%20(2).png)

Designers working on wetland boardwalks often ask similar questions at the beginning of the project: how can we simplify the permitting process, and how can we provide access to the area without harming the wetland itself?

We answer both those questions in this reference guide and help you explore whether the method of top down construction is right for your wetland boardwalk.

- Building a Wetland Boardwalk: The Design Phase

- Comparing boardwalk materials for wetland boardwalks using a top-down construction method

- What are the specific methods for building a wetland boardwalk with top-down construction?

- Total Cost Comparison for Building a Wetland Boardwalk Using 3 Methods of Top-Down Construction

- How to Build a Wetland Boardwalk: Considering Your Next Steps

Building a Wetland Boardwalk: The Design Phase

What to consider first in the design concept phase

When building a boardwalk over wetlands or an environmentally sensitive area, the question of permitting and reducing harm to the wetland should be discussed early on, in the concept phase of the design.

First, consider what is absolutely required and use that to determine the pros and cons of different potential construction methods.

Environmental regulations and permitting requirements at the local, state, or even federal level can dictate the construction method. In order to minimize harm to the wildlife and ecosystem, the boardwalk is mandated to be installed and built from above.

Sometimes, the wetland environment itself necessitates a boardwalk construction method like top-down construction. This was the case for our Shot Pouch Greenway boardwalk in Sumter, SC where super dense forest necessitated machines to install from the boardwalk itself.

The dense wetland forest necessitated top down construction for the Shot Pouch Greenway boardwalk in Sumter, SC. Read more about this project here.

Oftentimes though, many wetland boardwalks are permitted and built with marsh buggies or cranes placed on large mats in the wetlands. They DO NOT require top-down construction or installation from above.

While top-down construction has become more popular and requested, we highly recommend that other methods be considered if possible. As you will read in this article, there are potential downsides that could be avoided with other methods.

What does top-down construction mean as it relates to building a wetland boardwalk?

Top-down construction can have slightly different (but critically important for cost implications) meanings to various invested team members. The decision to employ a top-down construction approach is typically driven by environmental permit conditions. It is up to the designer to tell the contractor which scenario applies so they understand what is allowed during construction and can then determine how best to meet those requirements.

Taken verbatim at its strictest meaning, top-down could mean both the foundations and boardwalk are installed by not putting any equipment in the wetlands. This process drives installation time and precast boardwalk design.

A cost effective balance must be found between precast sizing and equipment sizing. This approach can also be a big factor in determining what foundation type can be used with your boardwalk.

Most boardwalk structures are not wide enough, or have sufficient structural capacity, to support large pile driving equipment (think falling weight and pneumatic hammers with long leads).

For example, the equipment required to drive precast concrete or steel H-piles will likely not be permitted to operate on a typical boardwalk. If this foundation is required due to geotechnical conditions, a separate frame may need to be constructed for the pile driving operation. Other foundation options might include timber, or FRP piles which can be installed using vibratory means, or helical piers.

In a nutshell, how does top-down construction work?

Once the foundation and equipment is determined, the actual process is pretty straightforward.

- The machine drives on top of the existing boardwalk surface segment to place the next section of foundation components and then beams & treads.

- Once that section is finished, the machine moves forward on the newly placed walking surface to continue installing the next portion.

- The process continues incrementally until the boardwalk is complete.

Throughout the process, the machine doesn’t drive directly on the wetland floor, reducing the footprint.

Here's a video showing another example of the top-down construction process for building a wetland boardwalk:

We're moving forward with top down construction: what else should boardwalk designers know in the concept and design phase?

Once everyone knows that top-down construction must be used, we recommend that the preferred top-down method be determined as early as possible. Boardwalk components can then be designed accordingly to support the construction equipment loads during installation. As a result, there is a reduced negative ecological impact, and the permitting process is usually simplified.

Once everyone knows that top-down construction must be used, we recommend that the preferred top-down method be determined as early as possible. Boardwalk components can then be designed accordingly to support the construction equipment loads during installation. As a result, there is a reduced negative ecological impact, and the permitting process is usually simplified.

You can find more about the 3 main methods later on in this article. Whichever method is chosen, notes regarding the method of top-down to be used, and allowable equipment should be included in the boardwalk drawing and specifications.

An obvious advantage to top down construction is the time and money saved on mitigation efforts. Additionally, undue damage to the fragile wetland will be avoided and the wetland itself will experience a faster self-healing period, recovering quicker, as most of the work was performed from above.

The wetland boardwalk design and installation method can be specified so contractors use top down construction techniques.

There are three primary benefits of top down boardwalk construction:

- permitting should be eased (in most cases)

- the construction footprint is reduced

- the wetlands will remain healthier.

Comparing boardwalk materials for wetland boardwalks using a top-down construction method

Below we’ll take a look at the pros and cons of three of the most common commercial boardwalk materials used for building a wetland boardwalk:

- pressure-treated timber

- composite decking

- precast concrete

Top down construction on a timber boardwalk

Timber boardwalks can be constructed using the top-down method. Specialty contractors are well equipped to design and install timber boardwalks using this kind of construction method.

In addition, special boardwalk applications in remote areas may require the boardwalk components to be hand carried into the project site. While this may require more individual laborers to move and transfer the material to the section being built, it can be done easily with timber planks, as the components are relatively light.

However, pressure-treated timber bends easily, and its shear capacity is much lower than concrete and would require many more stringers (runners) and possibly shorter longitudinal spans between piles to support the same load. In most cases, this results in more material, longer installation times and higher installation costs overall.

Similar to installing a concrete boardwalk with top down construction, for a traditional timber boardwalk, the foundations are installed first, typically spaced at 8’ to 10’ feet apart. Next, the headers and runners can be placed.

The headers and runners are placed with the same machine that installs the foundations, and the timber planks are individually screwed down. In the same way, the boardwalk components are moved to the end of the structure as it is built.

Top down construction with composite decking

One of the biggest drawbacks to using a composite decking material for wetland boardwalks is that the boardwalk is less likely to be built via the top down approach.

Most composite decking products are manufactured for residential uses and simply are not designed for heavy vehicle loading, whether that is a piece of construction equipment used during installation or a 10,000 lb. truck used by the Parks & Rec maintenance staff in the future.

In rare cases, boardwalk contractors have shared a more creative way to build a wetland boardwalk with composite decking. The boardwalk is built first with timber planks before the decking is removed as sacrificial material and replaced with composite decking.

This, in turn, increases the cost of materials, the time it takes to complete the boardwalk construction, and the cost of the installation overall. These factors often combine to eliminate composite decking from the conversation when designing a wetland boardwalk that must be built via top down construction.

Top down construction on a PermaTrak precast concrete boardwalk

If your project requires top down construction to minimize impacts to the wetland area, PermaTrak’s engineering team can assist with a structural analysis that defines the construction live load. It is well known that precast concrete is a stronger and much more durable material than timber or composite decking.

If your project requires top down construction to minimize impacts to the wetland area, PermaTrak’s engineering team can assist with a structural analysis that defines the construction live load. It is well known that precast concrete is a stronger and much more durable material than timber or composite decking.

As an inherently strong building material, precast concrete gives the installing contractor flexibility when it comes to choosing their equipment for construction, lowering construction costs.

With over 550+ boardwalk projects installed to date, we’ve seen massive cost savings passed on to the project owners when contractors have the opportunity to be cost-efficient by using either the equipment they already own or equipment that can be easily rented.

Something to be aware of however, is that as a heavier material, precast concrete may not be ideal in rare boardwalk installation scenarios when the boardwalk material must be hand carried onto the site location.

To begin construction, foundations are installed first and are often spaced 10’ to 15’ apart. PermaTrak precast concrete boardwalks can be installed on timber piles (shown below), helical piles, concrete piles or cast-in-place caissons. Next, the longitudinal concrete beams can be placed (shown in second photo below with concrete caissons).

.jpeg?width=600&height=490&name=build%20a%20boardwalk%20over%20wetlands%20timber%20piles%20(1).jpeg) Building a wetland boardwalk on timber piles using top down construction.

Building a wetland boardwalk on timber piles using top down construction.

.webp?width=600&height=450&name=build%20a%20boardwalk%20over%20wetlands%20concrete%20caissons%20(1).webp)

Building a wetland boardwalk on cast-in-place caissons using top down construction.

What are the specific methods for building a wetland boardwalk with top-down construction?

We’ve seen three different methods for top-down construction when building a boardwalk.

The first two methods apply top-down in its strictest sense: the equipment stays out of the wetlands and on the boardwalk itself.

The third puts equipment in the wetland, but only in the “footprint” of the boardwalk: allowing the foundations to be installed from mats on the ground.

Method 1: Helical Piers from Boardwalk

For this method, a smaller piece of construction equipment can install a helical pile foundation, the beams, and the treads while sitting on the boardwalk itself and minimizing disruption to the wetland environment. It should sit on matting or plywood to protect the treads.

The construction equipment in this example acts as a giant screwdriver, screwing in the helical piers in the ground.

Foundation Used: Helical Piers

Sample Construction Equipment Needed: Bobcat E 63 (13,800lb)

Bobcat E63, Source: www.worldhighways.com

Cost Impact: In comparison with Methods 2 and 3 below, Method 1 is typically significantly less expensive than Method 2, and slightly more expensive than Method 3.

Installation Time Impact: In comparison with Methods 2 and 3 below, Method 1 is typically slightly faster than Method 2 and 2-3x slower than Method 3.

Method 2: Vibrate Piles from Boardwalk

Similar to method 1, the construction equipment can install the foundation, beams, and treads while sitting on the boardwalk itself. Like method 1, the construction equipment should sit on matting; however, this should be more intensive load distribution mats designed by an engineer. As the boardwalk progresses, the matting is expanded to move with the equipment.

The construction equipment in this example shakes and presses the pile foundation (usually timber or composite) into the ground, vibrating rapidly to loosen the soil and applying pressure to drive the pile into the ground.

Foundation Used: Piles, often Timber or Composite

Sample Construction Equipment Needed: CAT 312 C Excavator (28,000lb)

CAT 312 C Excavator, Source: www.purplewave.com

Cost Impact: In comparison with Methods 1 above and 3 below, Method 2 is typically more expensive than Method 1 and significantly more expensive than Method 3.

Installation Time Impact: In comparison with Methods 1 above and 3 below, Method 2 is typically slightly slower than Method 1 and 2-3x slower than Method 3.

Method 3: Foundations Built from the Ground

Unlike methods 2-3 above, the foundations are not installed from the boardwalk itself. Instead, the piles are allowed to be installed from mats on the ground. Mats can be placed for a pile drill rig to move along these mats to install deep foundations.

With this method, heavier heavier driving equipment and higher capacity piles can be used, provided the mats can support the equipment. Once the piles are in place the matting is removed, and the boardwalk can be installed from above “top-down” with a smaller piece of equipment.

Foundation Used: Deep Foundations

Sample Construction Equipment Needed: Grove GHC30 Telescopic Crawler Crane (75,000 lb.) to install piles, Bobcat E50 excavator (11,500 lb.)

Grove GHC30, Source: www.manitowoc.com

Bobcat E50 Excavator, Source: bobcat.com

Cost Impact: In comparison with Methods 1 and 2 above, Method 3 is typically slightly less expensive than Method 1 and significantly less expensive than Method 2.

Installation Time Impact: In comparison with Methods 1 and 2 above, Method 3 is 2-3x faster than both.

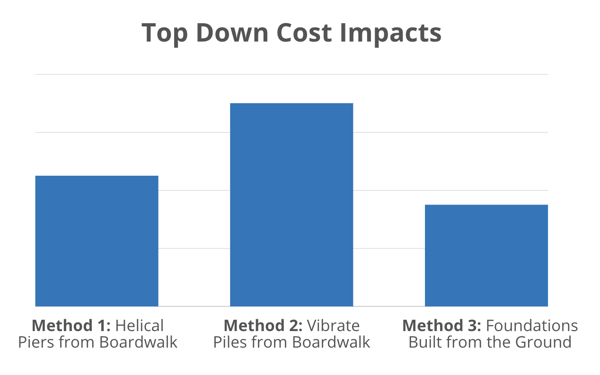

Total Cost Comparison for Build a Wetland Boardwalk Using 3 Methods of Top-Down Construction

As we can see from the chart below, the least expensive top-down method is typically Method 3. Method 3 also produces faster installation times than the first two methods.

The main drawback of Method 3 is that the larger construction equipment does need to sit in the wetland to install the piles; however, the disturbance can be minimized by the equipment sitting on mats as the foundations are installed.

The equipment mats can be installed within the boardwalk construction limits of disturbance further reducing impacts to the environment.

How to Build a Wetland Boardwalk: Your Next Steps

When designing a wetland boardwalk that requires top-down construction, determine the preferred method early and include specific notes in the plans so contractors understand the constraints.

The most cost-effective and fastest option is typically using construction mats and larger equipment to install deep foundations before switching to smaller equipment for installing the decking.

Carefully weighing environmental impact, cost, and schedule will lead to an optimal solution.

If you want to talk about this with a member of our design team, contact us by clicking this link.